Welcome to Septic-Tanks.ca of Saskatchewan & Manitoba

SCREWPILE ENGINEERING

Are you looking for screwpile engineering? Would you like to save money by building your own screwpiles? If you have a project coming up that requires screwpiles I can help you save money. You build the screwpiles and I will provide the engineering document.

The majority of building inspectors will ask for a document that says the screwpile you're installing will carry the load and built strong enough to withstand the torque. I have the information you need!

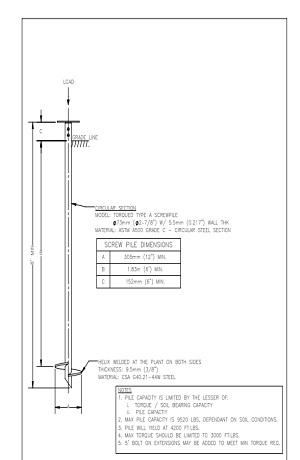

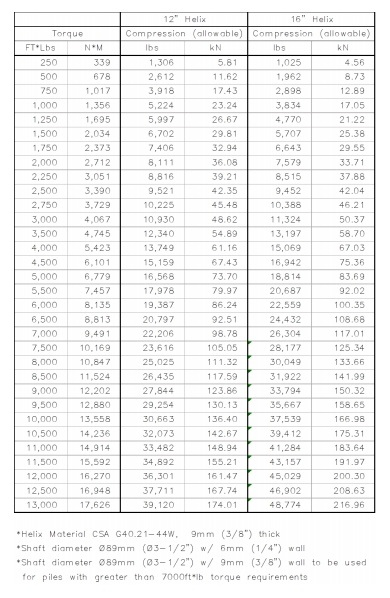

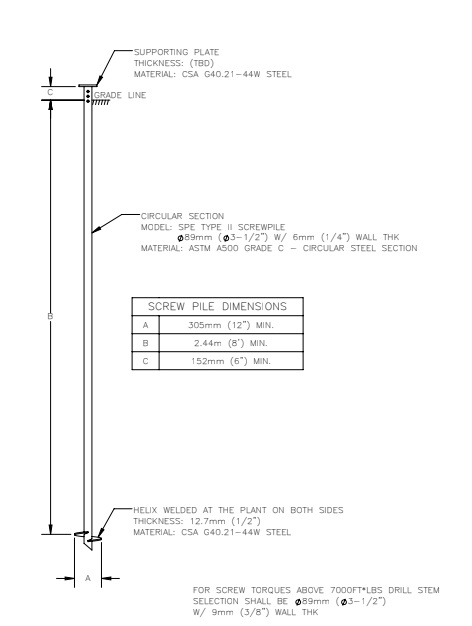

Below you see how a screwpile is built and the torque to load conversion table. The engineering stamp portion of the document has been removed but will be sent to your building inspector. The engineering can be bought for $20 per screwpile.

The job dictates what you need for a screwpile. For example, if you're building a deck you would use 2-7/8 pipe with a 12 inch flite or helical and it would be 8 feet long. Wind them in until they stop turning or until they are at your desired height. The torque for this screwpile would be 1000 to 3000 foot pounds. The hardness of the ground dictates the torque.

If you are building an addition on your house or have bought a mobile home, you would use 3-1/2 inch pipe with a 16 inch flite or helical and it will be 14-15 feet long. Grade beams and any type of foundation would need a 3-1/2 pipe and a 16 inch flite or helical. This application would be 4000 to 7000 foot pounds of torque.

When I'm installing a screwpile I wind them in until they stop turning or until they reach a height that suits the job. A 3-1/2 inch screwpile can torque up to 12,000 foot pounds before it stops turning. The main thing is to get them below frost....at least 6 feet deep is always my goal. Rarely would frost go more than 2-3 feet next to a building.

If you can build your own screwpiles, you can ask around for someone to install them. I can install for you if the travel time makes sense. How long does it take to install a screwpile? Time is based on site restrictions, the people on the ground helping and soil conditions. On average, I could install 4-5 per hr. I charge $200 per hour from the time I leave home until I return home.

Shop around and get prices from other installers and compare. I can help you with sourcing the helicals and the pipe, or I can supply it to you. Let me know if I can do anything to help with your screwpile project. Below are photo's of screwpile materials to give you an idea of what you need.

This picture is a 16 inch X 1/2 steel flite welded to a 3-1/2 drill stem. The flite is welded about 10 inches from the end of the pipe. The pipe is cut on an angle so it goes into the ground easier as it cuts the ground while it turns and can also loosen a rock so the flite can pass by easier. The pipe below the flite is to hold the screwpile in place until the flite starts cutting into the ground. The flite must be welded on both sides and wrapped around the ends.

This is a pallet of 16 inch flites for 3-1/2 pipe. We also use 12 inch flites and these are the only sizes you'll ever need for doing screwpile work in the housing industry and smaller commercial buildings. Alot of installers will use 2-7/8 pipe with a 12 inch flite or smaller for small jobs such as decks and grain bin anchors.

I buy 100-200 pipe at a time and it is alot of work to turn it into screwpile pipe. The pipe comes in 30 foot lengths. We cut the bell ends off then cut the pipe in half. The ends are cut straight but the middle is cut on a 45 degree angle. The angled end of the pipe is where the flite is welded on. As the picture shows, the pipe is evened up on one end and cut straight across 25 at a time.